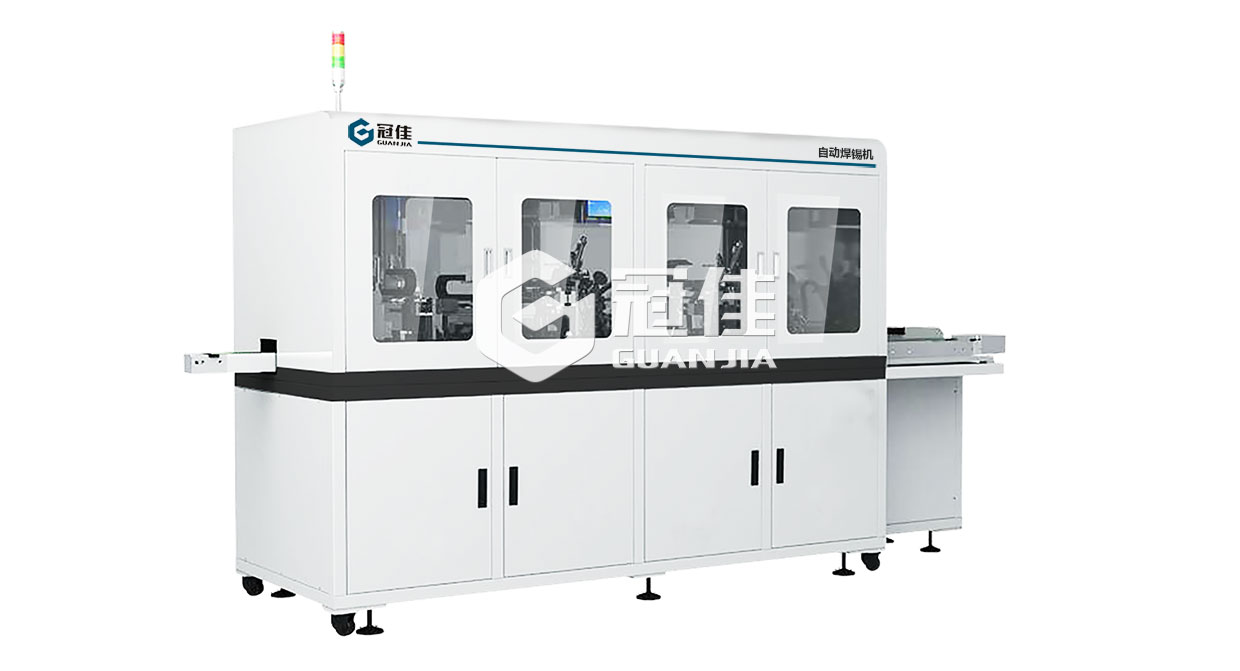

| GUANJIA Auto Solder Equipment |

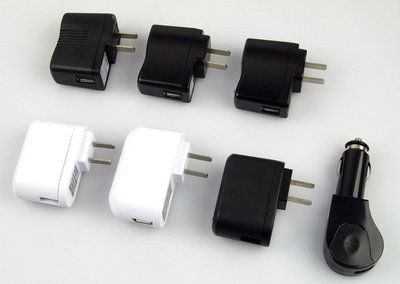

Charger / adapter AC / DC Welding Wire and USB

Our company has a large number of cases with mature technology ,as industry standard-setter for the industry, has been acquired patents. We have independently developed control software platform, also acquire related software work rights.

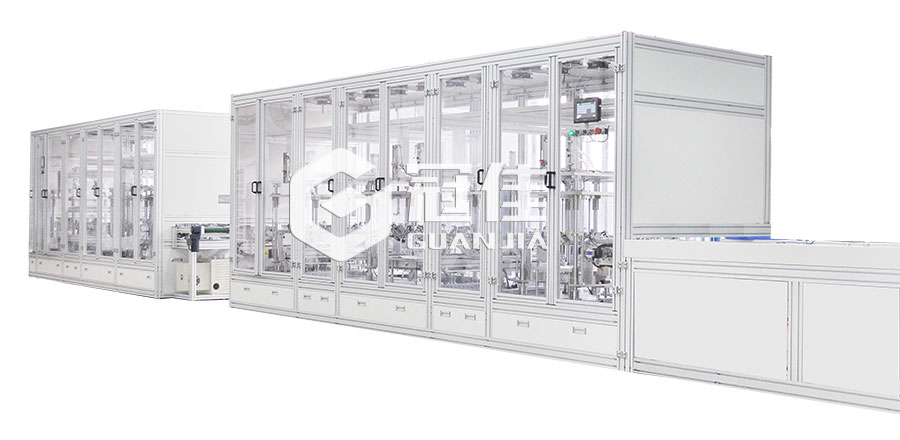

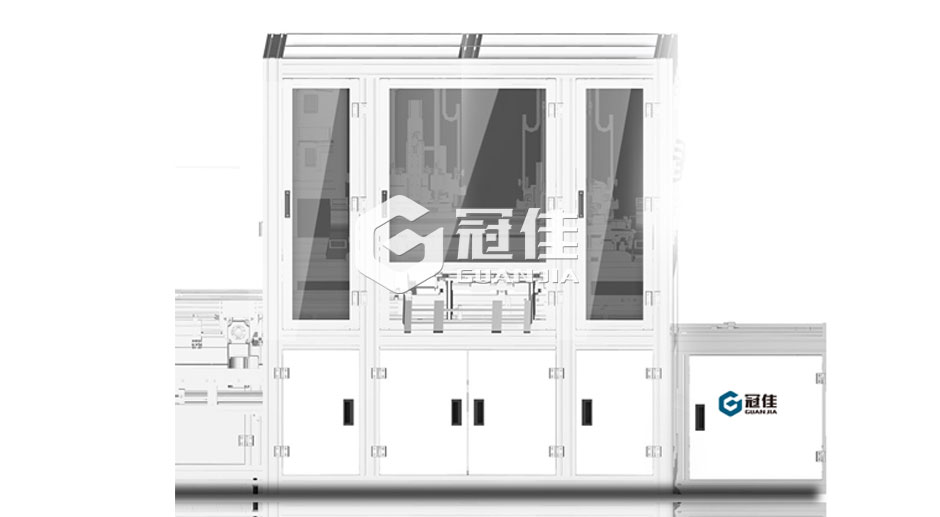

Each working bid or station adopts independent control system, stable and reliable, PLC+HMI+PC program controlling, simple operation and convenient maintain. |

Delivery fixture or jigs can be suitable for different machines and change production line of mould is very fast and high efficiently only change program. Automatic detection of weld quality with CCD, while automatic sorting poor and detection of the relevant data and reports according to user needs can be uploaded to the MES system.

To adopt Germany imported of send tin, tin broken, temperature control system, quality stable and reliable. |

The machine set concept has been through the flexible design ideas, front / rear smooth docking station, but facilitate for transferring the follow-up such as production lines or expand production capacity. Whole set machine of features are humane equipment, module, standards, design with energy-saving, nice appearance, simple structure, operation stable and reliable. Producted by GuangJia, It is will to be shared. |

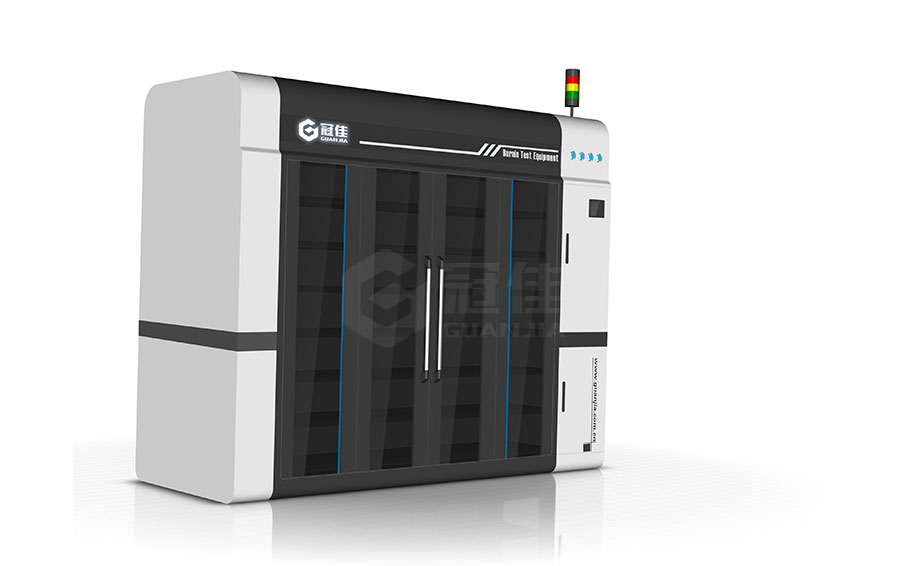

| Basic Profile | Equipment Model | GJAA-PS-R1 | |||

Equipment Function Description | Replace the manual for weld automatically : charger / adapter AC/DC joints | ||||

| Equipment Size (L*W*H) | 2800*1200*1950(MM) | ||||

| Tin pick pass yield rate | more than 98% | ||||

| Applications | Charger / adaptor of AC/DC Wire and USB Welding | ||||

| Time of production line | 15MIN | ||||

Main technology parameter requirements | Operation surface height of tracking way | 900+/-50mm Adjustable | |||

Production capacity per hour (UPH) | 1500 (Two joints) | ||||

| Welder working positioning | Double duplex positioning | ||||

| Equipment Supply / Voltage | Three-phases AC 380V | ||||

| Total equipment power | 5KW | ||||

| Gas source air pressure | 0.6MPa | ||||

| Product drive mothod | Fixture + belt + motor + governor | ||||

| Number of Gas source interface | one piece | ||||

| Motion Control System | Servo motor + straight module | ||||

| Iron head life time | 20000 Soldering joints | ||||

| Tin weld control system | Send tin system + get breaking tin system + temperature control system components imported from Germany | ||||

| Equipment weight: | 500KG | ||||

| Workflow Description: | Put PCBA into fixture by manual→ Photoelectric sensors to products and fixtures→ Product positioning mechanism for positioning the clamping fixture→ Soldering robot hand starts its operation →Welding is completed inflow AOI as for inspection →Product positioning mechanism for positioning AOI and start detecting jig →Machine automatic sorting NG and after finished → Down from the machine → idle jigs by lift and return line back to the previous seats which start point → the cycle as above | ||||

AOI inspection & bad quality processing | Number of welder joints inspection: | 2 joints | |||

| Inspection scope | Weld / continuing welding / Stacker tin / leakage welding phenomenon | ||||

| Poor data of processing | AOI analysis records in a computer can be uploaded to the MES system | ||||

| Sorting poor quality method | Mechanical material can be automatic sorting poor quality | ||||

Key standards working pieces Brands of usage requirements | Universal motor: | JSCC | |||

| Servo motor/driver | Inovance ( Shenzhen ) | ||||

| Screw guide track: | PMI or Hiwin | ||||

| Pneumatic Components: | SMC,FESTO (Domestic: EASUN, Air TAC) | ||||

| PLC/Extended: | Inovance ( Shenzhen ) | ||||

| sensor: | SICK, etc. or same class of brands | ||||

| Touch screen: | Inovance ( Shenzhen ) / (weinview) | ||||

| Industrial Personal Computer,IPC: | Advantech | ||||

| Switching Power Supply: | Mean Well | ||||

| Electrical Elements: | Teco / Chint | ||||