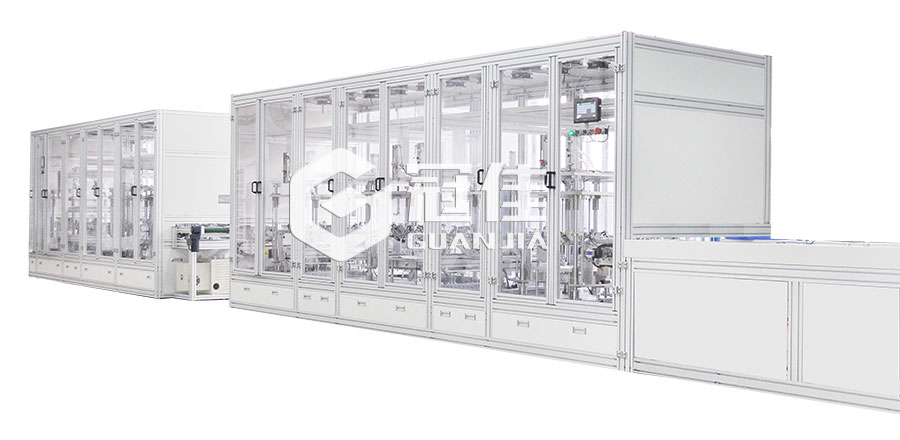

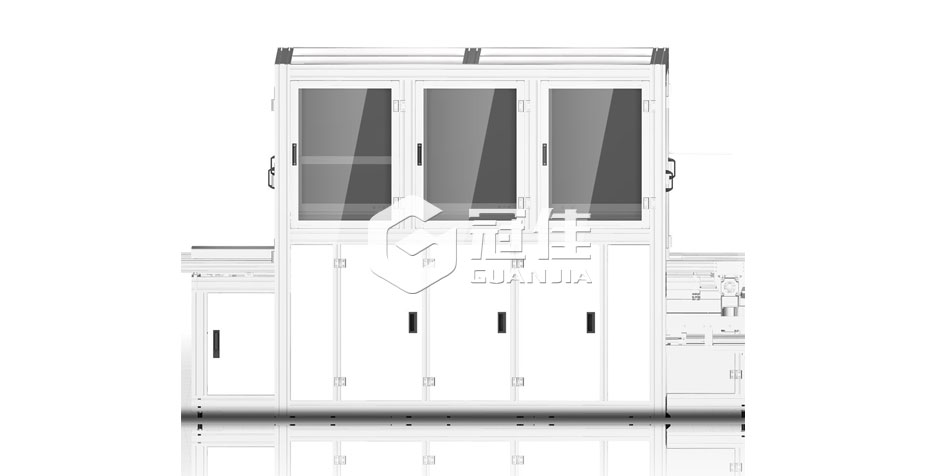

| GUANJIA Automated Assembly Equipment with Cover |

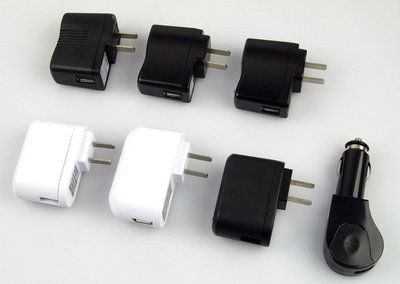

Chargers products with cover of assembled

Our company has a large number of cases with mature technology ,as industry standard-setter for the industry, has been acquired patents. We have independently developed control software platform, also acquire related software work rights. .

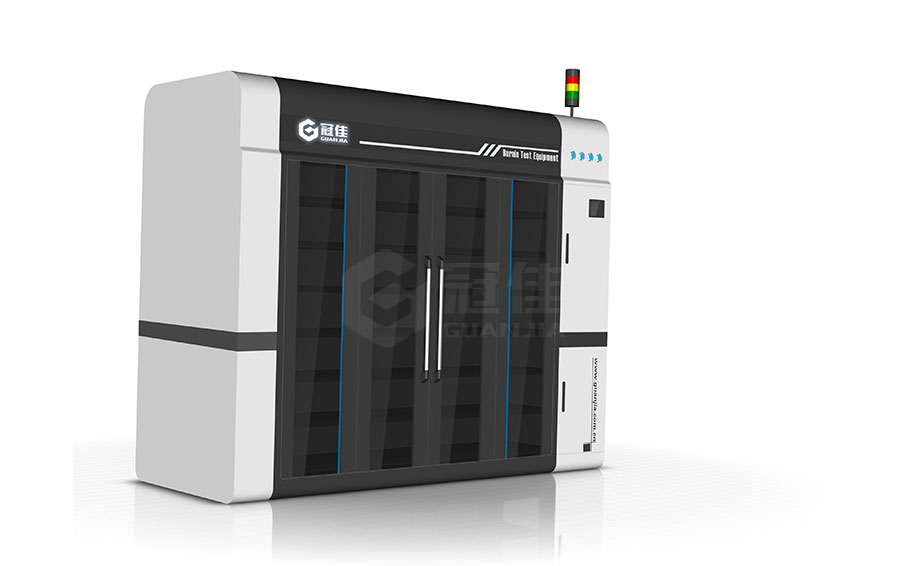

Each working bid or station adopts independent control system, stable and reliable, PLC+HMI+PC program controlling, simple operation and convenient maintain. |

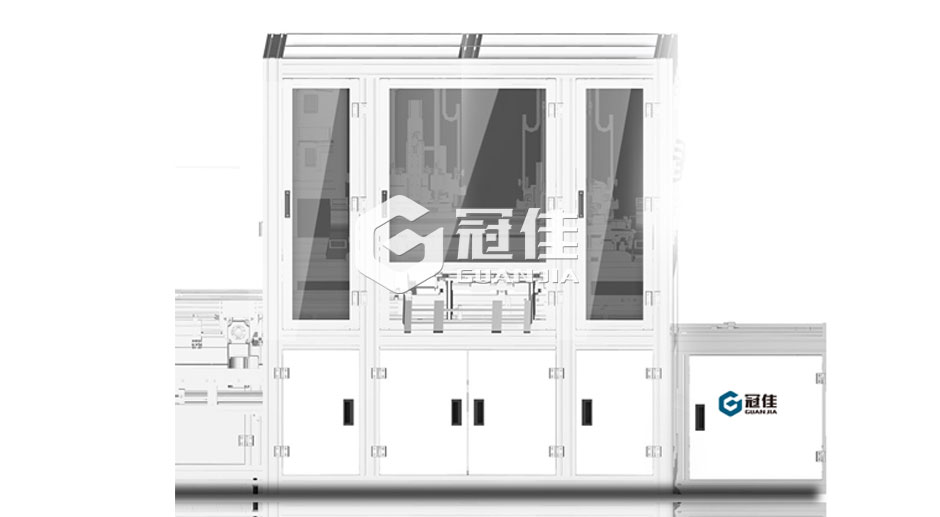

Delivery fixture or jigs can be suitable for different machines and change production line of mould is very fast and high efficiently only change program. To adopt XYZR Four-axis robot-hand & double duplex station for taking materials, much quickly

Use CCD for an image analysis processing, the assembly precision high and also high reliable. |

The machine set concept has been through the flexible design ideas, front / rear smooth docking station, but facilitate for transferring the follow-up such as production lines or expand production capacity. Whole set machine of features are humane equipment, module, standards, design with energy-saving, nice appearance, simple structure, operation stable and reliable.

After Charger cover is loaded into bottom of cover secondly press tightly and assure the cover assembly in the right position. |

| Basis Profile | Equipment Name | Equipment of auto assembly the cover above the charger | |||

| Equipment Model | GJAA-CHR-CC-V1 | ||||

Equipment Function Description | Put batter charger cover above into bottom of housing automatically, realize the manpower replacement | ||||

| Equipment Size (L*W*H) | 1800*1500*1800(MM) | ||||

| Product Applications | Battery Charger of Products | ||||

| Change Time of Production-line | 15MIN | ||||

Main Technology Parameter Requirements | Track-way Height of Operation Surface | 900+/-50mm Ajustable | |||

| UPH | 1500PCS | ||||

| Assembly Working piece station | Double duplex workstation | ||||

| Positioning Precision | ±0.02mm(X-Y-Z) | ||||

| Running speed | 800mm/sec(X-Y) | ||||

| Equipment Power/Voltage | Single-Phase AC220V | ||||

| Total Power of the Equipment | 3KW | ||||

| Gas source/air pressure | 0.6MPa | ||||

| Product transmission mode | Fixture + Belt + Motor + Governor | ||||

| Air source interface QTY | 1 piece | ||||

| Motion Control System | Motion Control Card or PLC | ||||

| Install PCBA of Structure | Imported four XYZR axis robot-hand and component | ||||

| Communication Method | Serial RS232C, computer communications software | ||||

| The feed supply way of Cover above | Belt conveyor line | ||||

| Intelligent Detection | CCD image + detection system | ||||

| Equipment Weight | 300KG | ||||

| Workflow Description: | Photoelectric sensors to products and fixtures→Product positioning mechanism for positioning the clamping fixture→Robot-hand starts for get operation→CCD image system for analysis & positioning the visual→Robot-hand automatically Loaded into PCB Housing→Cover above inflow to the being pressed, in the secondary in place tightly→After completing the inflow fixture getting off bits and go on next workstation | ||||

| Key Standard Working piece Brands of Usage requirements | Universal motor: | JSCC | |||

| Servo Motor / Drive | Inovance ( Shenzhen ) | ||||

| Screw guide track: | PMI or Hiwin | ||||

| Pneumatic Components: | SMC,FESTO(Domestic: EASUN, Air TAC) | ||||

| PLC/Extended: | Inovance ( Shenzhen ) | ||||

| Visual System | DaHeng | ||||

| Sensor: | SICK, etc. or same class of brands | ||||

| Touch Screen: | Inovance ( Shenzhen ) / (weinview) | ||||

| Industrial Personal Computer,IPC: | Advantech | ||||

| Switching Power Supply: | Mean Well | ||||

| Electrical components: | Teco / Chint | ||||