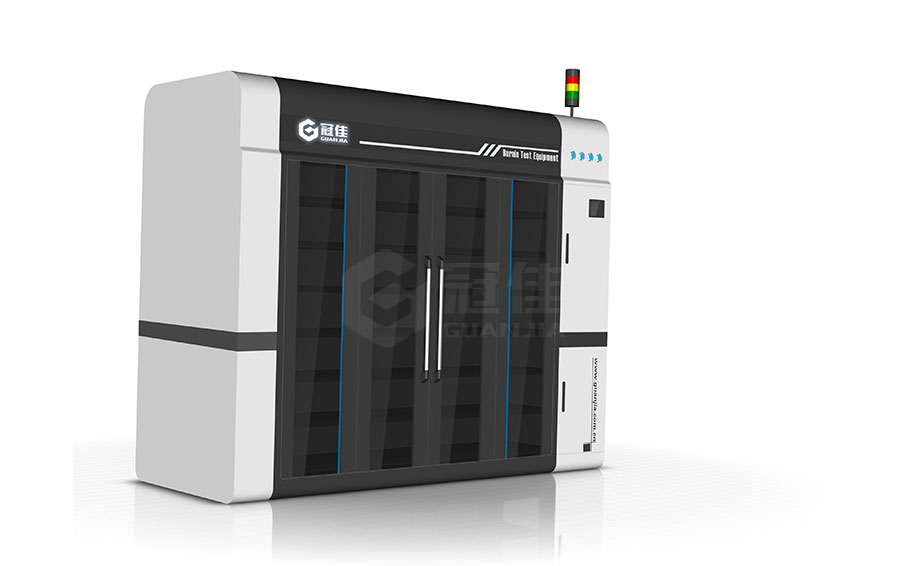

| Large Power Battery Charger Auto-test Equipment |

Final Test for 90W ~ 750W Server of power products after burnin

Pioneered for test the finished the power Supplies, become as the Universal or Standards applies to all categories Battery charger testing techniques. Pioneered the industry's first set high-power Battery Charger automatic testing equipment, innovative technique instead of the traditional manual testing .

It pioneered the industry's first set of the automated test equipment and testing instruments perfect butt, flexible and compatible with a variety of test equipment products.

With automatic test technology patents, and access to the automated software copyright, also ten years of industry experiences.

Our company has a large number of cases with mature technology ,as industry standard-setter for the industry, has been applied hundreds of automatic test equipment successfully. |

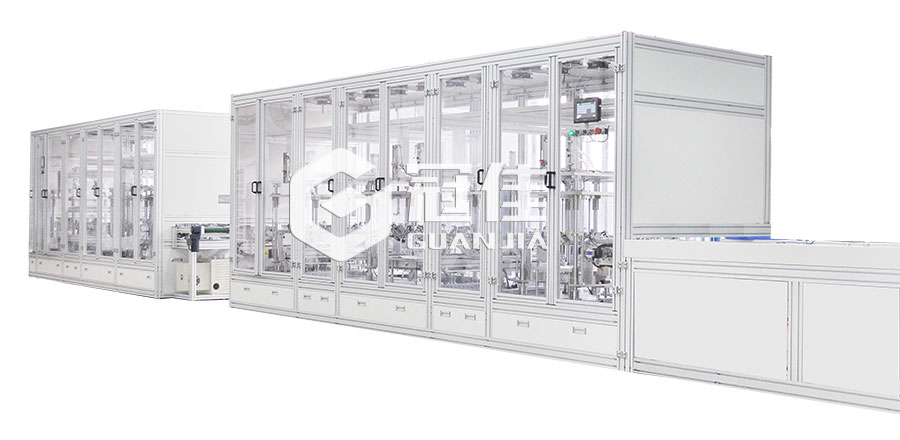

We have Standard control box has independently developed and tested software platform, adapted to different manufacturers of test equipment and communication protocols. Each working station using an independent control system, stable and reliable, PLC + HMI + PC program control, simple operation, easy maintenance.

Burnin test fixture shared more applicable models, models change working line just call the computer program no need to replace the other components.

The testing period status real-time display outside, real-time tracking to the NG products, the relevant data /reports can be upload / download according to user needs.

Each working station during the test independently of each other, smooth flow, and use a dedicated connector docking burnin, stable and reliable quality testing. |

Each station test with high efficiency, switching between instruments and test systems in response very fast, clever structural design and high utilization of the instrument. High utilization of space equipment, burnin and testing of electrical control cabinet control embedded inside the device, no additional space occupied by other field.

The machine set concept has been through the flexible design ideas, front / rear smooth docking station, but facilitate for transferring the follow-up such as production lines or expand production capacity.

The set is of humanity, modularity, standardization, energy-saving design, beautiful appearance, simple structure, reliable operation. GuanJia Brand, you deserve for having and enjoy them. |

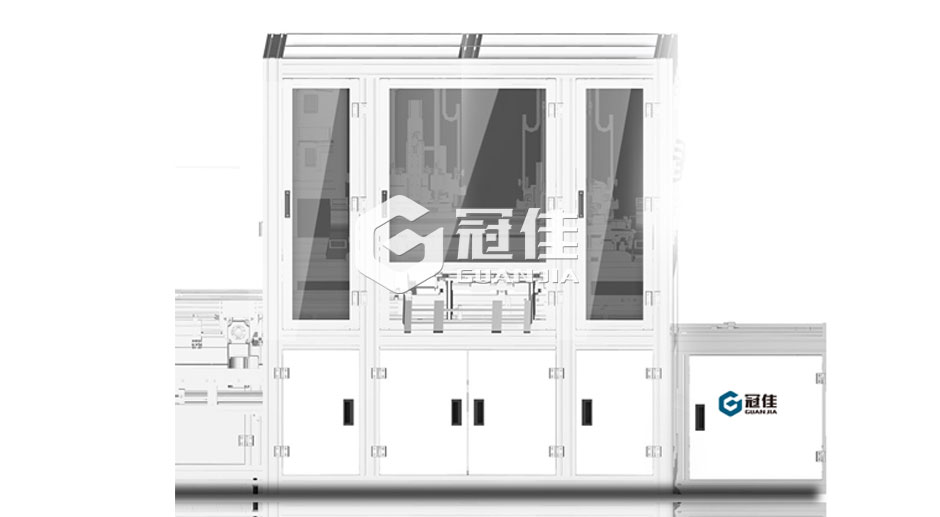

| Basic Profile | Equipment Model | TS20 | |||

| Equipment Function Description | In replace the manual operation, while achieving high-voltage power supply and function test after power burnin. | ||||

| Equipment Dimension(L*W*H) | 1300*900*1200(MM) | ||||

| Products Applications Scope | Standards for 90W~750W the Server products | ||||

| Production Line Change Time | None | ||||

Main Tech Parameters Requirements | The height of operation surface for track way | 900+/-50mm Can be ajusted | |||

| With function of the Idle jigs return back to fixture plate (panel) | Can be return back to the panel automatically & softly docking the working station Before and After | ||||

Equipment & instrument Transferred and connection mode | To use GuanJia Standards control-box + transferred and connection board | ||||

| Instrument Collocate Mode | To use standards instrument cabinet for put back of equipment | ||||

| Test Working Station | Double working bits or stations | ||||

| Equipment Power/Voltage | Single-phase AC220V | ||||

| Total Equipment Power | 5KW | ||||

| Gas Source and Air Pressure | 0.4~0.6MPa | ||||

| Transfer Method | Synchronous belt +motor + speed governor | ||||

| Track width adjustment range | 0~60MM | ||||

| Air supply ports quantity | 1 piece | ||||

| QTY network ports | 2 piece | ||||

| Equipment Weight | 160KG | ||||

Operation Flow Instruction: | Feed materials-->-->Block-->-->Read ID card information,Upload information --->--> Lifting jig is position--> --> Test cylinder into correct place, waiting for the test -->-->Testing-->-->Upload the testing data--> -->Insertion and removal of the cylinder let it down -->--> The lifting cylinder of decline -->--> The blocking releases --->--> Fixture or jig inflows getting off following bits or stations | ||||

| The destination for the Test relevant and participated interface | The high-voltage for test the highest-pressure | 3750V | |||

Communication Agreement Interface | GPIB、USB & RS232, etc. Configuration | ||||

| Specification for high-pressure set instrument | EXTECH 7440 or Chroma 19053/020 (Suggestion),also adapt other brands | ||||

| Specification for ATE Set instrument | Chroma8020(Suggestion),also adapt other brands | ||||

| Requirements for the interface of equipment & instruction | Output standards of interface Match with testing instruction | ||||

| Relevant information of equipment set & components | Products jigs dimension(L*W*H): | 290*498*140(MM) | |||

| Products jigs of materials | (Black) Phenoplast | ||||

| Products jigs Capacity: | 2PCS | ||||

| Products jigs Interface: | Standards plug | ||||

| Products jigs Weight: | 2.5KG | ||||

Key Standards Working-piece of Brands Usage requirements | Universal Motor | JSCC | |||

| Servo Motor/Drive | Inovance ( Shenzhen ) | ||||

| Screw guide track: | PMI or Hiwin | ||||

| Pneumatic Components: | SMC,FESTO (Domestic: EASUN, Air TAC) | ||||

| PLC/Extended: | Inovance ( Shenzhen ) | ||||

| Sensor: | SICK, etc. or same class of brands | ||||

| Touch Screen: | Inovance ( Shenzhen ) / (weinview) | ||||

| Industrial Personal Computer,IPC: | Advantech | ||||

| Switching Power Supply: | Mean Well | ||||

| Electrical Elements: | Teco/chint | ||||

Prev: Middle-Level Battery Charger Auto-test Equipment

Next: None