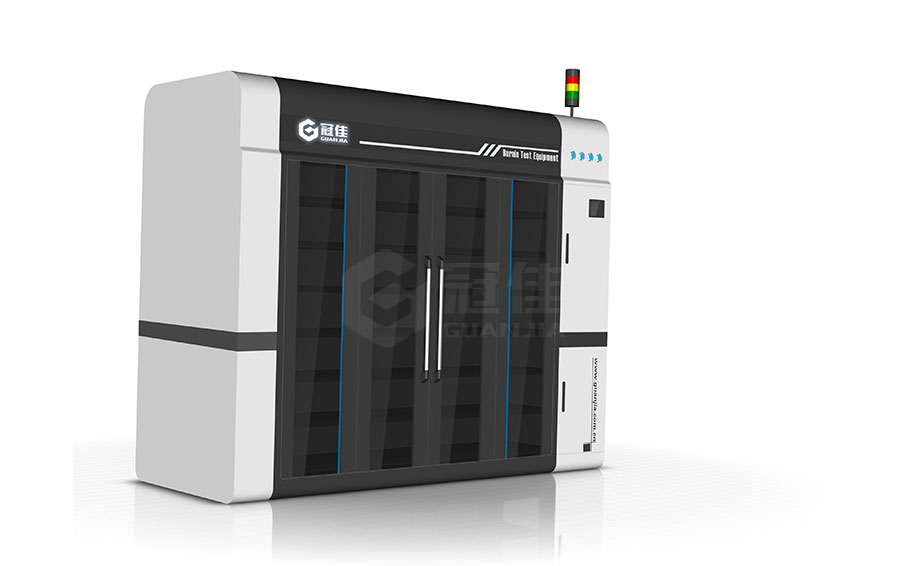

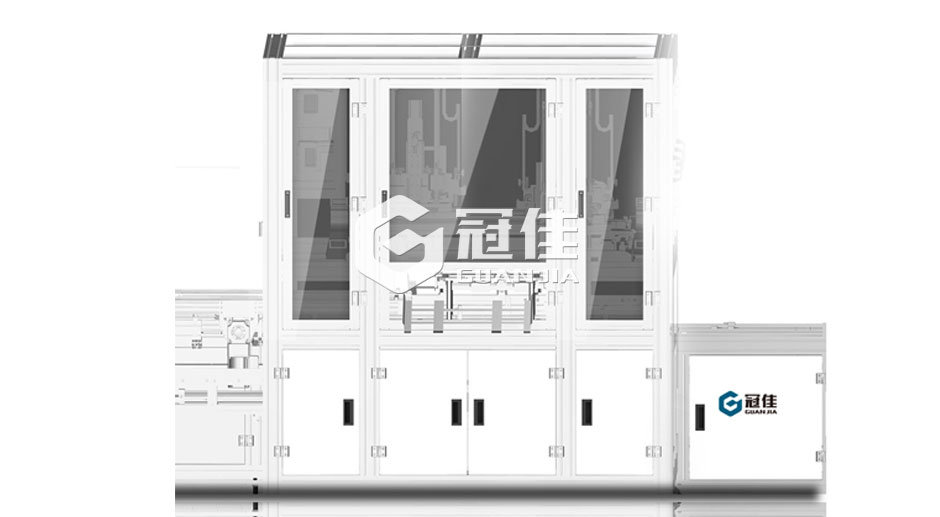

| GUANJIA AUTO Assembly PCBA Equipment |

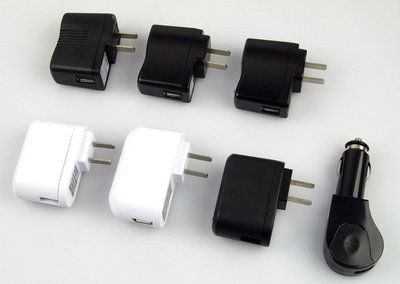

Batter Charge of Products Assembly PCBA

Our company has a large number of cases with mature technology ,as industry standard-setter for the industry, has been acquired patents. We have independently developed control software platform, also acquire related software work rights.

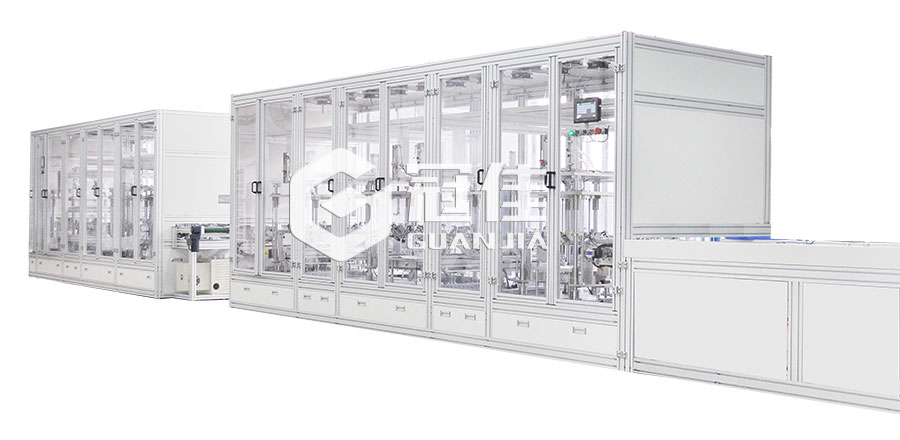

Each working bid or station adopts independent control system, stable and reliable, PLC+HMI+PC program controlling, simple operation and convenient maintain. |

Delivery fixture or jigs can be suitable for different machines and change production line of mould is very fast and high efficiently only change program. To adopt XYZR Four-axis robot-hand & double duplex station for taking materials, much quickly

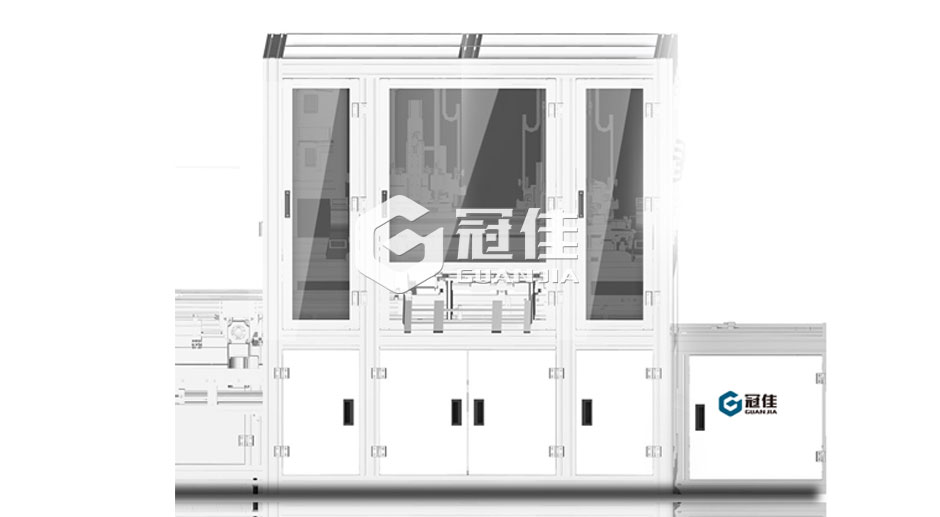

Use CCD for an image analysis processing, the assembly precision high and also high reliable. |

The machine set concept has been through the flexible design ideas, front / rear smooth docking station, but facilitate for transferring the follow-up such as production lines or expand production capacity. Whole set machine of features are humane equipment, module, standards, design with energy-saving, nice appearance, simple structure, operation stable and reliable.

After PCBA is loaded into bottom of cover secondly press tightly and assure PCBA assembly in the right position. |

| Basic Profile | Equipment Name | Equipment of auto Assembly PCBA | |||

| Equipment Model | GJAA-CHR-PC-V1 | ||||

| Equipment Function Description | Put into bottom of cover or housing of batter charger with PCBA automatically, realize the manpower replacement | ||||

| Equipment Dimension(L*W*H) | 1800*1500*1800(MM) | ||||

| Product Applications | Kinds of Battery Charger | ||||

Production-line Change need the time | 15MIN | ||||

Main Technology Parameters Requirements | Height of Track way Operation Surface | 900+/-50mm Adjustable | |||

| UPH | 1500PCS | ||||

| Assembly workstation | Double duplex workstation | ||||

| Positioning Precision | ±0.02mm(X-Y-Z) | ||||

| Running speed | 800mm/sec(X-Y) | ||||

| Equipment Power/Voltage | Single-Phase AC220V | ||||

| Total Power of the Equipment | 3KW | ||||

| Gas source/air pressure | 0.6MPa | ||||

| Product transmission mode | Fixture + Belt + Motor + Governor | ||||

| Air source interface QTY | 1 piece | ||||

| Motion Control System | Motion Control Card or PLC | ||||

| Install PCBA of Structure | Imported four XYZR axis robot-hand and component | ||||

| Communication Method | Serial RS232C, computer communications software | ||||

Feed Supply Mode of the Bottom Cover | Belt conveyor line | ||||

| Intelligent Detection | CCD image + detection system | ||||

| Equipment Weight | 300KG | ||||

| Workflow Description | Photoelectric sensors to products and fixtures→Product positioning mechanism for positioning the clamping fixture→Robot-hand starts for get operation→CCD image system for analysis & positioning the visual→Robot-hand automatically Loaded into PCB Housing→PCBA bit inflow being pressed in the secondary in place→After completing the inflow fixture getting off bits and go on next workstation | ||||

| Key Standards Working piece Brands of Usage requirements | Universal motor: | JSCC | |||

| Servo Motor / Drive | Inovance ( Shenzhen ) | ||||

| Screw guide track: | PMI or Hiwin | ||||

| Pneumatic Components: | SMC,FESTO(Domestic: EASUN, Air TAC) | ||||

| PLC/Extended: | Inovance ( Shenzhen ) | ||||

| Visual System | DaHeng | ||||

| Sensor: | SICK, etc. or same class of brands | ||||

| Touch Screen: | Inovance ( Shenzhen ) / (weinview) | ||||

| Industrial Personal Computer,IPC: | Advantech | ||||

| Switching Power Supply: | Mean Well | ||||

| Electrical Elements: | Teco / Chint | ||||

Prev: Automated Assembly Equipment with Cover

Next: None