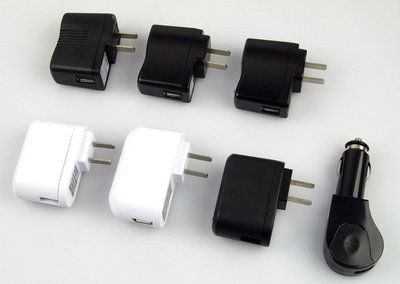

| Low-power charger Automatic Test Equipment |

Final Test for Low-Power Charger Products after Burnin

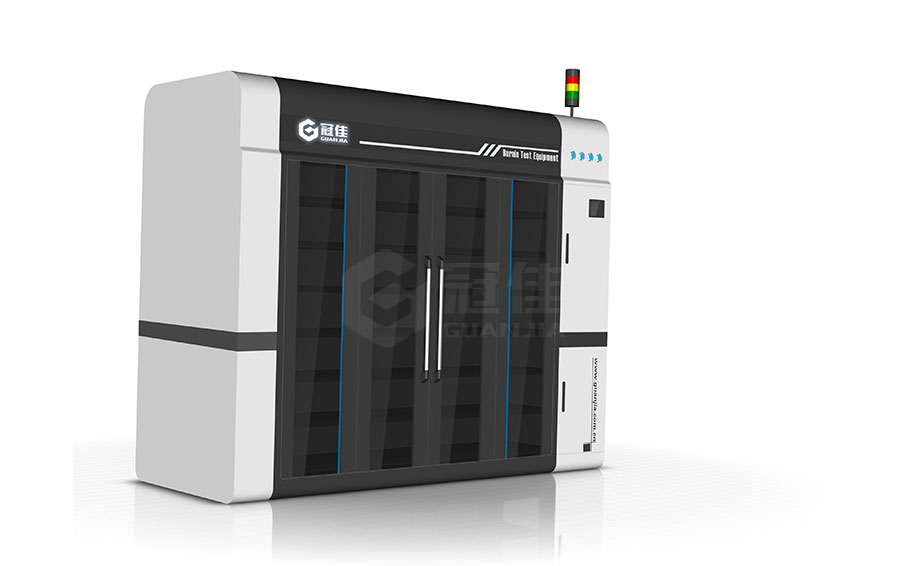

Pioneered the industry's first high-power power automatic burn-in system, to break the traditional of burnin, automatic burnin technology with innovation. Pioneered the industry's first low-power charger automatic test equipment, breaking the traditional pattern of manual testing, innovatively the automated testing techniques.

It pioneered the industry's perfect connection between the first set of the automated test equipment and testing instruments, products is flexible and compatible with a variety of test equipment.

Have with many patents on auto-test technology, and access to the automatic software work copyrights, more than ten years of industry experience.

Has a large number of application cases,mature technology, standard setters of industry, the industry has been successfully imported nearly 100 sets automatic testing of equipment . |

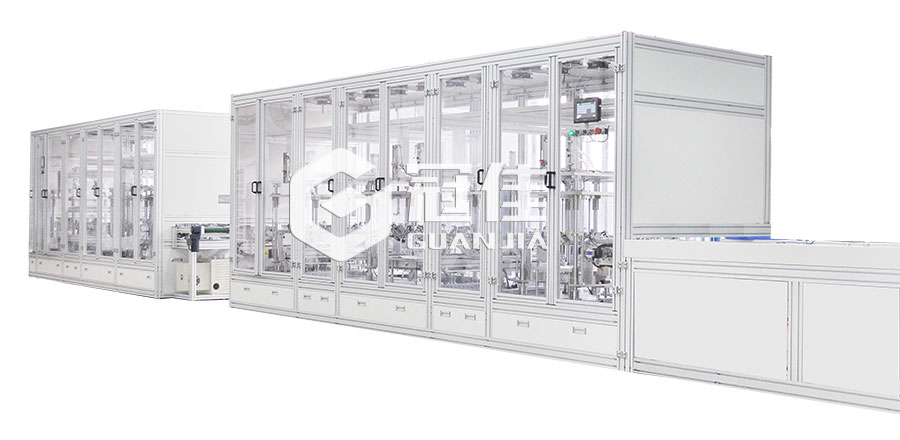

Standard control box has independently developed by ourselves and tested software platform, adapted to different manufacturers of test equipment and communication protocols. Each working station adopts independent control system,PLC + HMI + simple PC program control/operation/easy maintenance

Burnin test fixture shared more applicable models, models for line just call the program no need to replace the other components.

Real-time monitoring of the testing process, real-time tracking the bad , and reporting data according to user needs to upload / download. Each station during the test independently of each other, smooth flow, and use a dedicated connector docking burnin, testing quality is stable and reliable. |

Each station test with high efficiency, switching between instruments and test systems in response very fast, clever structural design, high utilization of the instrument. The equipment has high utilization of space, burnin control cabinet and testing of electrical control embedded inside the device, no additional space occupied by others.

Flexible design is going throughout the whole concept front and rear smooth docking stations each other, but also facilitate the follow-up production lines to expand production capacity or transfer production line.

The set machine is humane, modularity, standardization, energy-saving design, with beautiful appearance, simple structure, stable and reliable. GuanJia produced is good and worth we have them. |

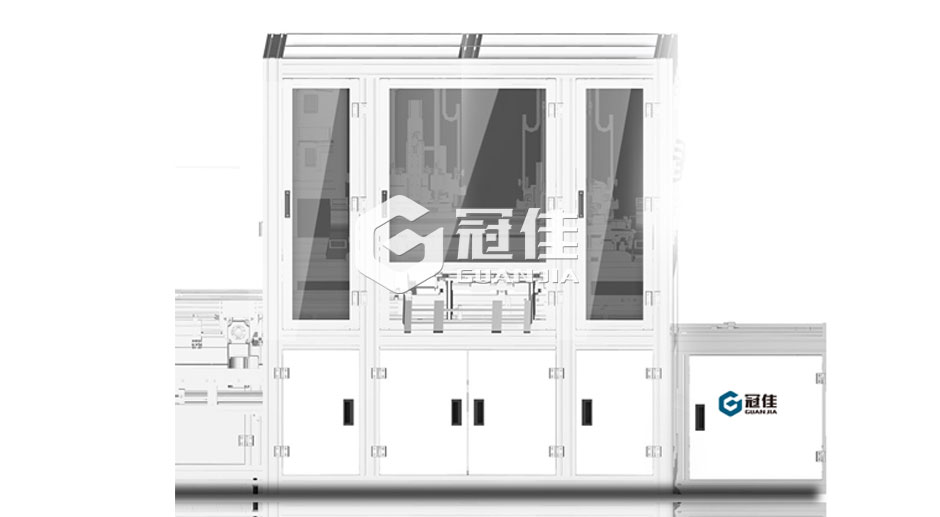

| Basic Profile | Equipment model | TC20 | |||

| Equipment Function Description | In replace the manual operation, while achieving high-voltage & function test after power supply burnin | ||||

| Equipment size(L*W*H) | 1200*900*1200(MM) | ||||

| Product applications | Commonly used to low-power charger products like 5 ~ 20W product categories | ||||

Production line Change time | No need time | ||||

Main technology Parameter requirements | Operation surface height of tracking way | 900+/-50mm Adjustable | |||

| Function of idle jig return back to plate | Can automatically back plate and the front and rear also being flexible docking station | ||||

| Equipment and instruments transfer connect mode | Use GuanJia standard control box + adapter plate | ||||

| Instrument layout mode | Using standard instrumentation cabinet to be placed in the back of the equipment | ||||

| Test station | Duplex station | ||||

| Equipment power and voltage | Single-phase AC220V | ||||

Equipment total power | 5KW | ||||

| Gas source and air pressure | 0.4~0.6MPa | ||||

| Transfer Method | Synchronous belt +motor + governor | ||||

| Adjust scope of track width | 60MM | ||||

Number of gas connection | one piece | ||||

| Number of network interface | 2 piece | ||||

| Equipment weight | 160KG | ||||

| Workflow Description: | Feeding ->block -> read the ID card information, upload information ---> lifting jig is positioned -> Test cylinder into correct place, waiting for the test -> -> Test -> upload the results data - > plug-cylinder being release-> lifting cylinder is decreased->block is release ---> fixture inflow the next and getting off bits | ||||

| Definition for testing to the related participation interface | The highest voltage test for test the highest pressure | 3750V | |||

| Communication protocol interface | GPIB, USB & RS232 etc. configuration | ||||

High-pressure supporting Instrument specifications | EXTECH 7440 or Chroma19053/020 (The suggestion),also suitable for other brands | ||||

ATE supporting instrument specifications | Chroma8020 (The suggestion),also suitable for other brands | ||||

| Requirement of equipment and instrument interface | To be output standard interface and matching the test instrument | ||||

Equipment configuration components relevant information | Product of fixture size(L*W*H) | 270*580*90(MM) | |||

| Product fixture of materials: | Black ABS+PC | ||||

| Product fixture capacity: | 16PCS | ||||

| Product fixture interface: | AC: tripod or feet plug DC: standard DC head | ||||

| Product fixture weight: | 1.5KG | ||||

Key standard brands usage requirements | Universal motor: | JSCC | |||

| Servo motor/driver | Inovance ( Shenzhen ) | ||||

| Screw guide track: | PMI or Hiwin | ||||

| Pneumatic Components: | SMC,FESTO (Domestic:EASUN, Air TAC) | ||||

| PLC/Extended: | Inovance ( Shenzhen ) | ||||

| sensor: | SICK etc. or same class of brands | ||||

| Touch screen: | Inovance ( Shenzhen )/ (weinview) | ||||

| Industrial Personal Computer,IPC: | Advantech | ||||

| Switching Power Supply: | Mean Well | ||||

| Electrical Elements: | Teco / Chint | ||||